In recent years, the industrial fiber laser market has developed rapidly and has a strong momentum. The market competition for medium and low power fiber lasers is fierce and has entered the stage of price competition. Controlling costs has become an important means for fiber laser manufacturers to participate in market competition. The market demand for high-power fiber lasers is urgent and the market gap is huge, but its nonlinear effect suppression is difficult, and fiber laser manufacturers are seeking new solutions.

With the maturity of the temperature control technology of industrial fiber lasers for pump sources, the application of 976nm band pump sources in industrial fiber lasers has gradually been recognized and accepted by the market. The fiber laser gain fiber has a high absorption efficiency for the 976nm band pump source, which can effectively reduce the manufacturing cost and pumping technology difficulty of industrial fiber lasers. Many technologically advanced fiber laser manufacturers have focused their technical solutions on the 976nm band pump solution in order to gain greater market advantages as soon as possible.

Application Advantages

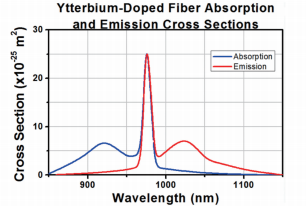

Industrial fiber lasers achieve energy conversion from pump light to signal light through gain fiber (ytterbium-doped fiber). Ytterbium-doped fiber has two obvious characteristic absorption peaks in the 915nm and 976nm bands. The absorption coefficient in the 915nm band is relatively low and the absorption spectrum is wide; the absorption coefficient in the 976nm band is 2-3 times that of the 915nm band (as shown in Figure 1), but the absorption spectrum is relatively narrow.

The pump light energy provided by the 915nm/976nm pump laser corresponds to the absorption peak characteristics of the ytterbium-doped fiber. In the past, many fiber laser manufacturers used the 915nm band pumping solution because the wider absorption peak of the ytterbium-doped fiber in the 915nm band can make up for the pump wavelength drift caused by the wider temperature control range of the fiber laser. However, the lower absorption coefficient of the 915nm band pump source brings double obstacles in cost and technical application, limiting the development trend of high-power and low-cost fiber lasers.

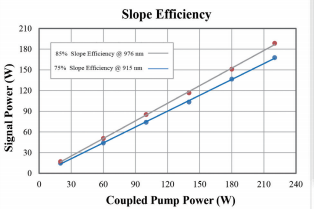

For fiber lasers pumped in the 976nm band, the gain fiber has a higher absorption coefficient for pump light. According to practical feedback from many domestic fiber laser manufacturers, the optical efficiency of 976nm band pumping can reach 85%, while the optical efficiency of 915nm band pumping is 75% (as shown in Figure 2). Under the same pump power injection, compared with 915nm band pumping, the output power of the fiber laser will be 13% higher when using 976nm band pumping, and the gain fiber length required by 976nm band pumping is shorter, which directly reduces the material cost while effectively reducing nonlinear effects, optical efficiency loss, and thermal management difficulties. However, 976nm pumping has higher requirements for fiber laser temperature control.

Cost Advantage

With the development and maturity of the technology of domestic fiber laser enterprises, the market share of domestic lasers has steadily increased, especially for medium and low power fiber lasers, which have basically achieved domestic substitution. With the increasing homogeneity of medium and low power fiber laser products, market competition has become increasingly fierce. Since the 2019, it has entered the stage of price competition. The cost of fiber lasers faces huge market challenges. In order to reduce costs, many fiber laser manufacturers have set their sights on 976nm pump sources. The higher optical-to-optical conversion efficiency of the 976nm pump source can effectively reduce the cost of the pump source. Taking a 1500W fiber laser as an example, the 976nm pump source has an electro-optical efficiency of about 10% higher than that of the 915nm pump source, which will directly save 235W of pump source power, greatly saving the manufacturing cost of fiber lasers, and also saving about 11% of the electricity consumption costs for the end users of fiber lasers, effectively helping mid- and downstream users to establish market competitive advantages.

In the past, semiconductor lasers in the 915nm band were used as pump sources. Benefiting from the wider absorption spectrum of the 915nm band, the laser was less affected by temperature. However, the absorption efficiency of the gain active fiber in the 915nm band was low. In order to achieve a higher power output of the fiber laser, it was technically required to use a higher 915nm pump power and a longer active fiber. This would cause developers to face many difficulties, such as the nonlinear effect of the gain fiber, the loss of optical efficiency, the increased difficulty of thermal management, and the increase in unit wattage cost. When the output power exceeds a certain level, the 915nm pumping solution will become extremely complicated and eventually fail.

Using the 976nm band pumping solution will solve the above difficulties of the 915nm band pumping solution. The absorption efficiency of gain fiber in the 976nm band is 2-3 times that of the 915nm band. Higher absorption efficiency means that the required gain fiber is shorter, which brings about a series of technical advantages such as reduced nonlinear effects. It also saves some material costs of gain fiber. In addition, the cost advantage brought by optical efficiency (the optical efficiency of the 976nm band pump source is about 10% higher than that of the 915nm pump source) further reflects the cost-effectiveness of the 976nm pumping solution in high-power fiber lasers.

When thermal management is no longer an obstacle to the 976nm band pumping solution, the dual advantages of technology and cost of the 976nm pumping technology are reflected.

Our address

B-1508 Ruiding Mansion,No.200 Zhenhua Rd,Xihu District

Phone Number

0086 181 5840 0345

info@brandnew-china.com