Classification and Application of Laser Marking Machine

Laser marking machines use laser beams to mark permanent surfaces on a variety of different materials. The effect of marking is to expose deep materials through the evaporation of surface substances, thus engraving beautiful patterns, trademarks and words. The laser marking machines currently used on the market are mainly divided into the following major types:

1. Fiber laser marking machine

The fiber laser marking machine uses a fiber laser. The fiber laser has the characteristics of small volume (no waterless device, air cooling), good beam quality (base mode), and maintenance-free.

Mainly used in: plastic, electronics, metal, ceramics, tobacco and other materials on the marking of the required text, graphics, barcodes and other graphics.

2. UV laser marking machine

The UV laser marking machine was developed using a 355 nm UV laser. The 355 UV focused spot is extremely small, which can greatly reduce the mechanical deformation of the material and has little effect on processing heat. Mainly used in enterprises with higher requirements for text, graphics and other products.

3. Semiconductor laser marking machine

The main application industry is the same as the fiber laser marking machine, but as the market competition becomes more and more fierce, the advancement of fiber technology is getting faster and faster. Semiconductor laser marking machines on the market have been slowly replaced by fiber laser marking machines.

4. CO2 laser marking machine

CO2 laser marking machine is mainly used in some non-metallic industries such as food, medicine, leather, tobacco, wood products and electronics. The effect of marking is more delicate and beautiful than the effect of silk screen printing and inkjet printing.

5. End pump laser marking machine

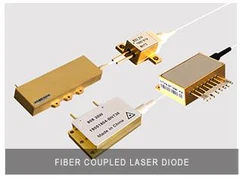

The end face laser marking machine uses a solid-state laser pumped by a semiconductor laser as a pump source, and is coupled to the laser crystal from the end face via fiber coupling. The pump beam enters the gain medium to overlap the cavity mode to the maximum extent, so that high power and high beam quality laser output can be obtained.

The main application industry is also the same as the fiber laser marking machine, and its performance is similar to that of the fiber laser marking machine, but its peak power is higher.

6. Green laser marking machine

Mainly used in the surface and internal marking of glass and crystal products, ceramics, metals, electronics, plastics and other products. It belongs to the category of cold light, and it is also suitable for some products that have a relatively high heat response and high precision.

7. Flying laser marking machine

It is a dynamic marking function developed on the basis of the above several laser marking machines. It is mainly applied to the assembly line. It can be marked on the product for 360 days without restriction. It can also automatically generate the serial number and batch number, thus greatly improving the enterprise. Production efficiency.